transposed conductor

Classification:

Details

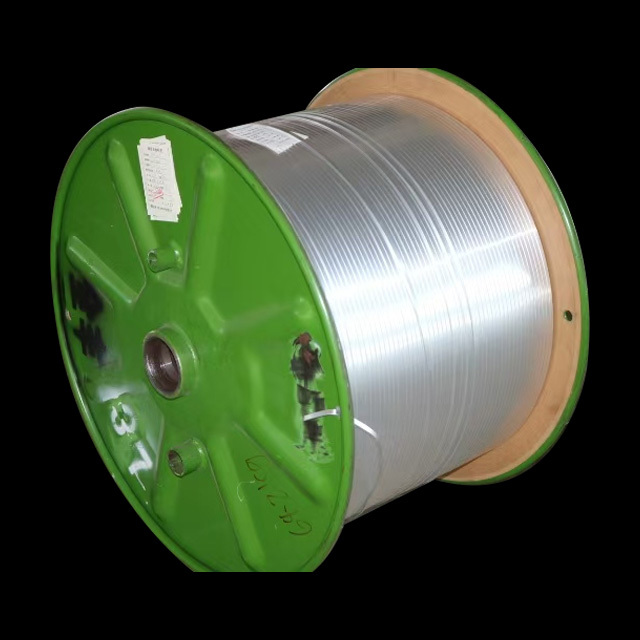

Transposed wires are made by arranging a certain number of enameled flat wires in two columns in a special process and continuously weaving them with specific insulation materials.

A winding wire made by wrapping materials. Mainly used for manufacturing windings of large oil immersed power transformers, reactors, and large capacity dry-type transformers. By using transposed wires to manufacture transformers, the space utilization of windings has been improved, the volume has been reduced, and the cost has been lowered. Additionally, the additional commutation and eddy current losses caused by leakage magnetic fields have been reduced,. At the same time, it also has the advantages of improving the mechanical strength of the winding and saving winding time.

Continuous transposition wire is an important material for manufacturing transformer windings.

Product range:

Paper insulated aldehyde enameled transposition wire

Paper insulated self-adhesive acetal enameled transposition wire

Paper insulated self-adhesive semi-rigid aldehyde enameled transposition wire

Paperless binding type aldehyde enamel coated transposition wire

Ladder transposition combination wire

Internal screen transposition combination wire

Polyester imine enameled transposition wire

Polyvinyl alcohol and polyester film insulated transposition wire

Production scope:

Number of transposed roots: 5-80 roots (odd or even numbers are optional);

Dimensions: Height 120mm, width 26mm (tolerance ± 0.05mm);

Single conductor size: thickness a: 0.90-3.15 mm, width b: 2.50-13.00 mm (tolerance ± 0.01mm);

The recommended width to thickness ratio for a single conductor is: 2.0<b/a<9.0;

The recommended coating thickness for enameled wire is 0.08-0.12 mm, and the adhesive layer thickness is 0.03-0.05 mm.

Keywords: transposed conductor

Recommend products

Online Message

If you are interested in us, welcome to leave a message!